The Department of Materials Technology and Production Systems invites companies and other research units to collaborate on our scientific research and innovative projects. We offer unique collaboration opportunities that can bring tangible benefits to our partners.

We offer:

-

Access to the latest technologies: Our laboratories are equipped with modern equipment, enabling advanced research and testing.

-

Scientific expertise: Our scientists are recognized experts in their fields, ready to share their knowledge and experience.

-

Tailored projects: We offer the possibility of implementing research and development projects tailored to the specific requirements of your company.

-

Networking and partnership: Collaboration with us also means the opportunity to establish contacts with other industry leaders and participate in prestigious conferences and scientific events.

Development of modern materials and technologies:

-

Designing new materials based on: Al, Mg, Cu, Fe, and other metals,

-

Selection of materials for machine parts,

-

Alloys resistant to abrasive and adhesive wear,

-

Heat treatment of alloys,

-

Designing innovative construction solutions with plastics,

-

Computerized quality control system for liquid alloys using the ATD method, ISO 9001-TÜV certification for laboratory research,

-

Development and improvement of technologies:

-

3D design, reverse engineering,

-

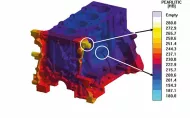

computer simulations: mold filling process, alloy solidification in molds, thermal stresses, mechanical properties of castings,

-

casting in synthetic molding compounds,

-

precision casting using the lost wax method,

-

"Lost foam" casting,

-

permanent mold casting,

-

intensive cooling of ceramic molds,

-

controlling solidification and casting properties through localized cooling,

-

thermographic analysis of the solidification process of aluminum alloys in intensively cooled molds,

-

artistic casting.

-

Development of manufacturing methods:

-

Simulation modeling for the analysis of complex systems, MRP / ERP, Lean Manufacturing, TPM, SPC, FMEA, 5S, ISO 9001.